Views: 29 Author: Site Editor Publish Time: 2021-04-13 Origin: Site

The roller conveyor is suitable for passing all kinds of boxes, bags, and pallets, as well as some loose or irregular materials. In contrast, the roller conveyor for the industrial application can convey some bulky goods and bear a large impact load. It is usually simple in structure, mainly including of the roller, frame, bracket, driving part, and so on. It is easy to operate and maintain, high reliability, large conveying capacity, and fast speed. Now, let's go on to find out more details about the industrial conveyor system.

Take the conveyor system in the aluminum extrusion as an example. The initial table belongs to an ultra-high temp zone. It refers to the area in front of the extruder exit, which can reach up to 500°C or more. As a result, only galvanized iron roller covered with PBO heat-resistant felt tube (working temp: 600℃) can meet the requirement.

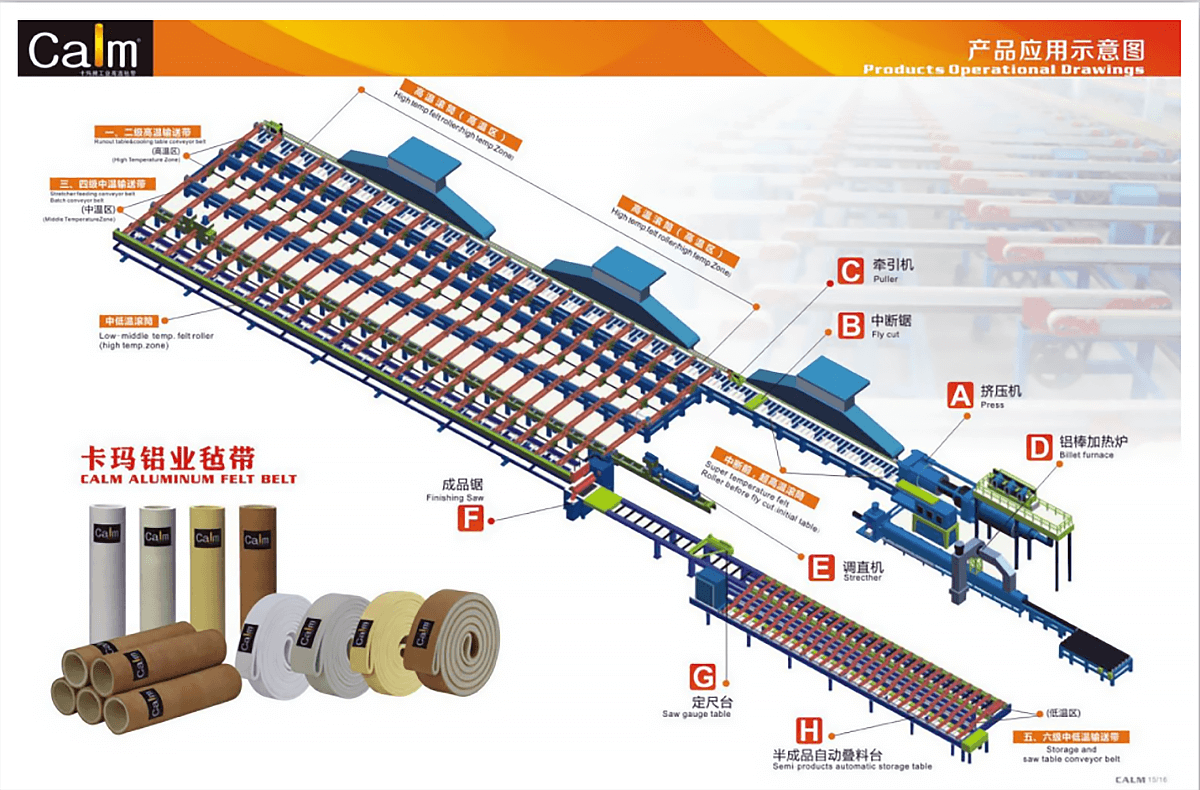

Conveyor System in Aluminum Extrusion Line

As you can see in the picture, the whole conveyor system mainly consists of the felt roller and the felt belt. That is why it can meet various production process needs such as stretch, cooling, and handling. Here are some things you should know about the operation of the roller conveyor.

1. The workers should take pre-job training to get familiar with the roller conveyor operation before they start work. In case of emergency, they can properly deal with it in time to reduce losses and safety accidents. Don't forget that safety and operating instructions should be clear and easy to understand.

2. No matter what kind of equipment, they all require inspection and maintenance after a period of time. And the felt roller conveyor is no exception. It is a must to lubricate regularly to ensure smooth running to reduce wear.

3. The roller conveyor should be cleaned up in time after use. It helps to prevent some wastes from getting stuck between the rollers. Otherwise, the felt roller line can not run in a normal way, which will reduce work efficiency.

4. To some extent, the roller felt cover is does not require a lot of maintenance. All you need to do is to replace them regularly. But as for the galvanized steel roller, you do not need to replace them as often. Just be careful to use mild cleaning agents to prevent surface corrosion.

5. The roller conveyor line has a specific power rating. In other words, it has a load-bearing range. Therefore, you should ensure that the load does not exceed the limit to avoid fracture or collapse during production. In addition, don't try to overload the felt rollers at the time of startup, too. It is an ideal way to reduce wear and tear, which can extend the service lifespan.

As for calm felt roller cover, full resin or semi-resin treatments are available to improve durability and wear resistance. It also prevents aluminum swarf and dirt from sticking to the felt, and reduces damage to the surface of the aluminum profile. Besides, we offer a variety of guidance and solutions based on different needs. If you want to know more about that, please feel free to contact us at toby@gdcalm.com.