Views: 315 Author: Site Editor Publish Time: 2019-12-18 Origin: Site

The working principle of aluminum profile extruder is a physical deformation principle. It uses ancillary equipment such as electromagnetic heating furnaces or coil induction heating furnaces to heat the aluminum rods to about 450 ° C and then extrudes them with an extruder.

The principle of the extruder is that the aluminum rods heated by the device in the extruder barrel are propelled at one end. The other end is the corresponding mold. Under the pressure output of the hydraulic system, the extrusion rod pushes the aluminum rod toward the mold. After the aluminum rod is physically deformed from the mold at high temperature, it will become the corresponding aluminum profile and then it will be cooled and sawed.

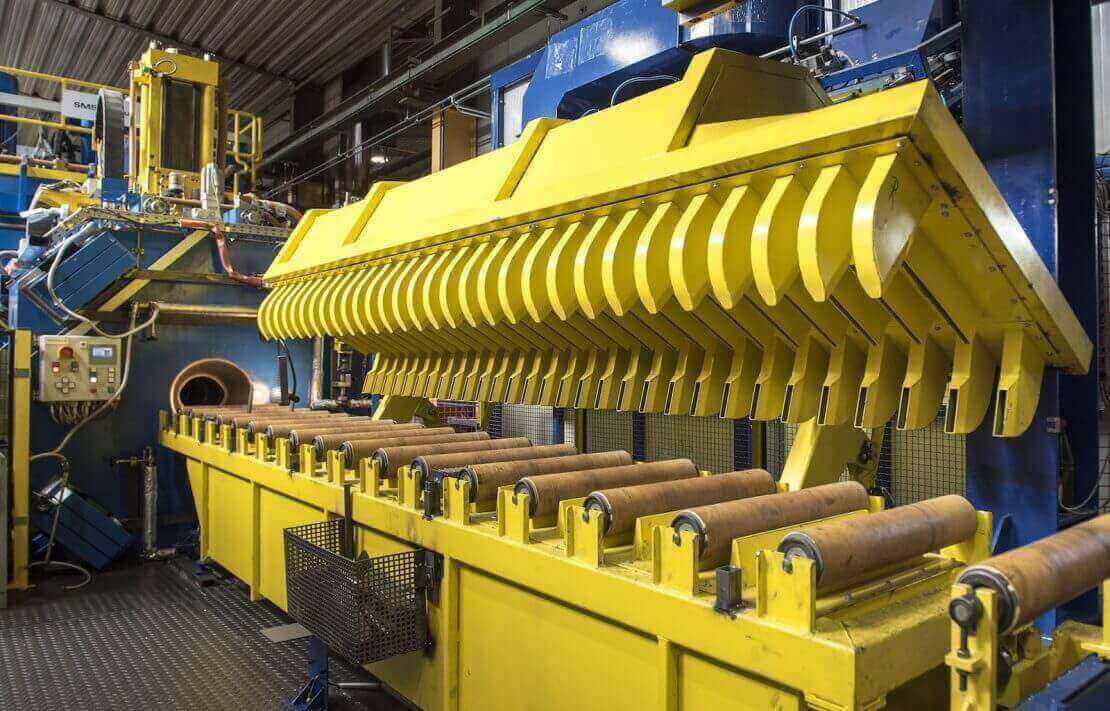

PBO felt roller for Aluminum Extruder

Aluminum alloy profile extrusion has many characteristics, mainly including the state of stress and strain that occurs during the extrusion process, metal flow behavior, the comprehensive quality of the product, the diversity and flexibility of production and production efficiency and cost.

It can be pressed to join metal powder, chips, and other metals;

The thin-walled hollow asymmetric product can be formed by using a split die;

It can process aluminum alloy materials with low plasticity;

It can form complex irregular sections and products;

It is possible to process the blanks of the outer cover with the cover material that prevents oxidation and surface cracks.

The extruder is mainly composed of three parts: mechanical part, hydraulic part, and electrical part.

The mechanical part is composed of a base, a pre-stressed frame-type tension column, a front beam, a movable beam, an X-shaped extruded barrel seat, an extruded shaft, an ingot supply mechanism, a residual material separating shear, a sliding die seat, etc.

The hydraulic system is mainly composed of the main cylinder, a side cylinder, a lock cylinder, a perforated cylinder, a large-capacity axial plunger variable pump, an electro-hydraulic ratio servo valve (or an electro-hydraulic proportional control valve), a position sensor, an oil pipe, an oil tank, and various hydraulic pressures.

The electrical part is mainly composed of a power supply cabinet, an operating table, a PLC programmable controller, a high-level industrial control machine, and a display screen.

The structure of the whole machine adopts a four-pillar horizontal type with the fuel tank on top. It has features of a new structure, neat arrangement, and convenient maintenance.

The movable beam adopts four-point positioning, adjustable center, and reasonable tool and dies design, which can greatly reduce production costs.

Different extrusion processes can be set. Follow-up and fixed needle methods are used to extrude pipes with different apertures.

The hydraulic parts use a large flow cartridge valve system, which has good sealing performance and low-temperature rise.

PLC products are used for electrical parts, which are reliable and sensitive.