Views: 49 Author: Site Editor Publish Time: 2021-03-12 Origin: Site

Nowadays, some modern factories often use automated sorting equipment and assembly lines to transport. And this is also true for the production of aluminum profiles. We all know that only at very high temperatures(around 500℃) can press and form aluminum profiles. That means heat resistant felt belt is vital for the whole conveyor system, which can realize continuous conveying from feeding to unloading. Here are something you may not know about it. Let's read on and check it out!

1. Place the materials above the conveyor in order without overlap. And pay attention to the leakage of materials that stay between the conveyor and the belt. Otherwise, it will fail to work in the right way.

2. In general, turn on the conveyor felt belt under no-load conditions. In other words, any overload start-up is harmful to the conveyor. It will cause the starting engine to burn out, which will greatly affect the normal running.

3. Each conveyor has different load capacity. Be careful that the load should not exceed this range during daily use. Or else, the load-bearing device may damage even break, which will lead to safety accidents.

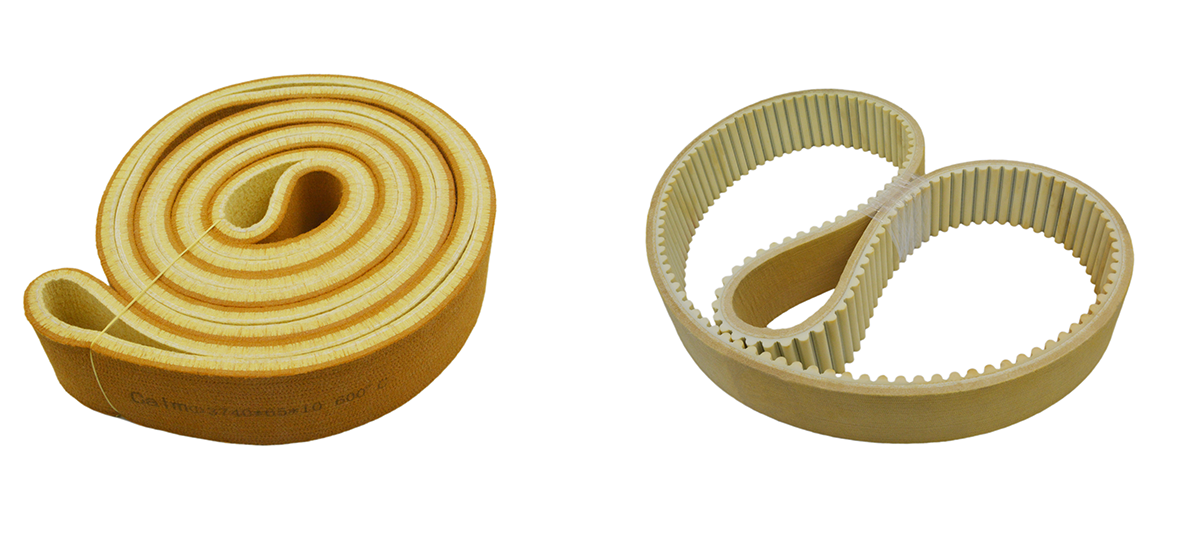

Industrial Felt Belt & Heat Resistant Timing Belt

4. The load problem is also works for the conveyor felt belt. High risk of breakage under heavy loads (over 3000T) if using ordinary felt belts. In this case, timing belts with heat resistant felt is the best alternative.

5. Workers must not interfere with the operation of the high temp conveyor belt to avoid accidents. In case of an emergency, use the braking device to shut down the conveyor operation. And then carry out the adjustment according to the relevant regulations.

6. When the felt belt goes off track, shut down the running, and take timely measures to correct it. There are many reasons for off-track, such as low installation precision and poor daily maintenance. So be sure you are cooperating with a professional felt belt supplier.

7. Avoid the conveyor conveying device suffer from the rack, pillar, or block material block. It can help to prevent broken or tear and reduce the impact of normal transportation. So don't forget to clean up in time and place tools neatly. Besides, pay attention to the lubrication of the movable part of the conveyor belt in peacetime.

8. When using the high-temp resistant conveyor belt for a period of time, there should be relevant management personnel to check. Regular inspection is a must for conveyor felt belts. It is necessary to analyze and deal with the resulting problems according to the actual situation on time.

In fact, there are many other things you need to pay attention to regarding conveyor belts. However, everything will be easier after you choose Calm. We are one of the top suppliers of industrial felt products in China. If you want to know more information, please feel free to contact us at toby@gdcalm.com. We are looking forward to hearing from you!